Welding Machine

As one of the foremost welding machine suppliers in China, we can offer a wide range of welding machines to the global customers, such as wheel rim butt welding machine, wire mesh welding machine, filter tube welding machine, 3D panel welding machine, steel grating welding machine, boiler fin tube welding machine, 3D truss girder welding machine, roll welding machine, dust collector bag cage welding machine, can welding machine, tank welding machine, and some others.

-

- Wheel Rim Bending Machine

We can provide all the related machines for producing wheel rims, such as rim bending machine, rim butt welding machine, rim trimming machine, rim rolling machine, and so on.

-

- Wire Mesh Welding Machine

This mesh welding machine is of full automatic, PLC control.

The space between longitudes is adjustable before welding.

The space between each woof can be preset in the PLC.

-

- Wedge Wire Filter Tube Welding Machine

This Wedge Wire Filter Tube Welding Machine is specially-designed for welding filter tubes for any filtering purposes in chemicals, mining, environmental protection, as well as many other industries.

-

- 3D Panel Welding Machine

This 3D panel welding machine is used to produce structural reinforced concrete panel, also called "3-D" panel. This three-dimensional panel usually adopts 50mm thick uninflammable polystyrene panel as core. One side or both sides of the panel are covered with steel wire welded mesh.

-

- Steel Grating Welding Machine

This steel grating welding machine is composed of gantry type welding machine, double-layer flat steel feeding device, cross bar auto falling device, steel grating hauling device, hydraulic & pneumatic system, cooling system, electric control system, etc.

-

- Concrete Pipe Cage Welding Machine

DC power can assure the welding speed, prolong the life of welding electrodes and save at least 30% electric consumption

PLC, inverter, touch screen are imported

Densely-wind length on both ends of the cage and the hoop reinforcement interval can be pre-set on the touch screen.

-

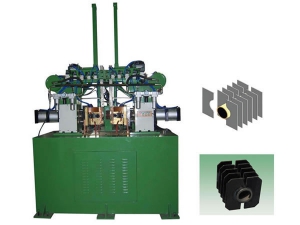

- Dust Collector Bag Cage Welding Machine

As the name implies, the dust collector bag cage welding machine is particularly offered for manufacturing bag cage for dust collector. The welding machinery is quite popular home and abroad because of the stable performance.

-

- Spiral Fin Tube Welding Machine

The high frequency spiral fin tube welding machine adopts PLC for double frequency conversion linkage control on the product.

The material loading, clamping, feeding, welding, and material unloading can be completed automatically.

-

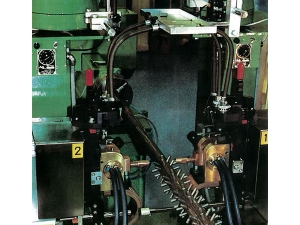

- H gilled boiler fin tube welding machine

Controlled by PLC, the H Gilled Boiler Fin Tube Welding Machine offers semi-automatic production. The production process includes manual steel pipe feeding, manual fin tube unloading, manual fin loading, and automatic fin delivering. The fin spacing and length can be set up on the PLC. Importantly, the fin spacing for one tube can be varied.

-

- Pin Finned Tube Welding Machine

This pin finned tube welding machine employs Siemens SINUMERIK802 control system for easy and simple operation. The pin finned tube welding device is generally used to weld the steel pin to the base pipe for boilers. High automatic, the welding equipment is capable of completing pin feeding (2 heads), welding, indexing, base tube feeding, etc.

-

- Tank Welding Machine

This welding machine is composed of welding center and clamping device. It is applicable to various different tanks, ideal for straight seam welding and circle seam welding. Please contact us for further information on our tank welding machine.

-

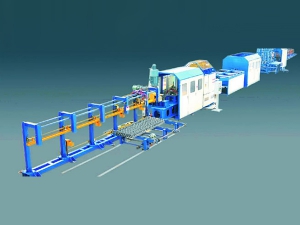

- 3D Truss Girder Welding Machine

The 3D truss girder welding machine utilizes three coiled steel ribbed bars and two coiled round steel bars as the raw material for production.

The 3D truss girder is a kind of advanced invention for building construction.

-

- Automatic Tin Can Welding Machine

The automatic tin can welding machine is applicable for the production of various round tin can product, inclding paint can, oil tank, adhesive can, food can, artwork, etc.

-

- Spiral Sand Control Filtration Screen Tube Welding Machine

The spiral tube welding machine conducts TIG welding and plasma non-stop cutting to produce sand control filtration screen tubes for the petroleum and chemical industries.

English

English Español

Español Русский

Русский Português

Português Français

Français العربية

العربية