- Home

- Products

- Welding Machine

- H gilled boiler fin tube welding machine

H gilled boiler fin tube welding machine

Description

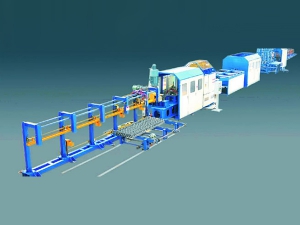

Our H-gilled boiler fin tube welding machine is developed for manufacturing fin tube composed of single or twin pipes. The fin tube is widely used on the boilers. This fin tube welder consists of push trolley, pneumatic system, welding unit, and support frame.

Controlled by PLC, the H-gilled boiler fin tube welding machine offers semi-automatic production. The production process includes manual steel pipe feeding, manual fin tube unloading, manual fin loading, and automatic fin delivering. The fin spacing and length can be set up on the PLC. Importantly, the fin spacing for one tube can be varied.

Capacity of H-gilled Boiler Fin Tube Welding Machine

| Item | Specifications | |||

| Suitable H gilled fin tube length | 1-15m | |||

| Suitable H gilled fin thickness | 2-3mm | |||

| Suitable base steel pipe diameter | 19-51mm | |||

| Applicable material | Base tube | Carbon steel | Carbon steel | Stainless steel |

| Fin | Carbon steel | Low-carbon steel alloy | Stainless steel | |

Technical Parameters of H gilled Boiler Fin Tube Welding Machine

| Item | Specifications |

| Welding power source | Intermediate frequency inverter, 160kVA×3 |

| Welding transformer cooling method | Compulsive water cooling |

| Silicon controlled rectifying diode | ABB from Swiss, 12 pieces |

| Active welding electrode | Be-Co-Cu alloy |

| Welding electrodes pressing force | 2500N |

| Pneumatic cylinder for pressing & positioning | Airtec from Taiwan |

| Annealing unit for welding section | Annealing period is adjustable. |

| Welding speed | < 4s (for 38.1mm base tube & 3mm fin) |

| Welding strength | >50MPa or base tube torn |

| Width of welding seam | Larger than fin thickness |

| Welded fin length tolerance (full length) | ±1mm |

| Welded fin length tolerance(fractional) | ±0.5mm |

| Fin pitch tolerance | ±0.1mm |

| Pendicularity between fin and base tube | ±1° |

| Height difference between fins | ±0.2mm |

| Center distance between two tubes | ±0.2mm (for twin-tube) |

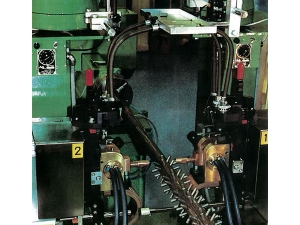

Photo of H gilled Boiler Square Fin Tube

English

English Español

Español Русский

Русский Português

Português Français

Français العربية

العربية