Pipe / Tube Forming Machine

There are many kinds of tube/pipe making, rolling and processing machines, like post-tension corrugated pipe forming machine, spiral filter core forming machine, flexible hose forming machine, steel pipe welding machine, tube swaging machine etc. Post-tension corrugated pipe forming machine is perfect for producing round and oval corrugated pipes, which are widely used in expressway, bridge, train and large-span post-tension concrete project; spiral filter core forming machine is especially suitable for producing spiral steel core for automotive filters; and the flexible hose forming machine is used to produce flexible hose in double seam lock (double-swage); steel pipe welding machine is used for producing round, square, rectangular steel pipes for different industrial and civil use; tube swaging machine is manufactured for producing decorating tubes. Having established a reputation for its high quality, our tube / pipe forming machine is very popular in the international markets.

Welcome to use Haoshuo tube / pipe forming machine!

-

- Post-tension Pipe Forming Machine

Being suitable for both indoor and site work, this post-tension pipe forming machine is perfect for producing round & oval corrugated pipes, which are widely used in expressway, bridge, train and large-span post-tension concrete project.

-

- Spiral Filter Core Forming Machine

Any length can be cut according to customer's requirement.

By adjusting clutch, the spiral forming machine can be suitable for materials of different thick.

Adopting PLC control system, this forming machine offers high efficiency, stable quality, less procedures and materials, thus reducing the production cost.

-

- Metal Flexible Hose Forming Machine

This forming machine is used to produce flexible hose in double seam lock (double-swage). Its materials include stainless steel, cooper, carbon steel and aluminum. The finished hoses are mainly used for sanitary and electric wiring, etc.

-

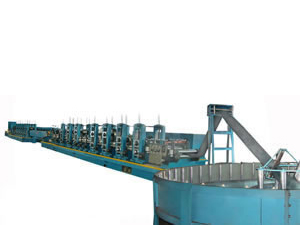

- ERW Pipe Machine

This machine is an ideal tool for producing straight-seam welded round, square, rectangular and special pipes with the diameter ranging from 10mm to 610mm. High frequency welding method is adopted.

-

- Tube Swaging Machine

Tube swaging machine is mainly used to produce decorative metal tubes. Haoshuo is able to provide a variety of swaging machines, such as twisting machine, tapering machine, rotary type swaging machine, tube spinning machine, tube bending machine, and so on.

-

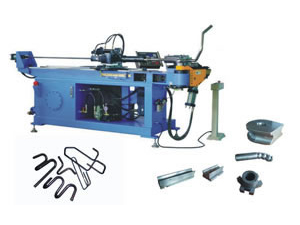

- CNC Tube Bending Machine

Three-axis numerical control, hydraulic clamping

Gear and rack driving, each axis is equipped with high precision planetary reducer

Tracking die is restored pneumatically

CNC control, 12.1” touch screen operation, simple and easy

-

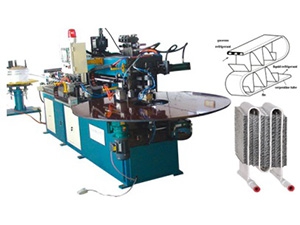

- Serpentine Tube Bending Machine

We provide two different serpentine tube bending machines: one for bending microchannel flat aluminum tubes used in automobile evaporators, and another for bending round metal tubes for heat exchangers.

-

- Tube Spinning Machine

Two axis CNC control, small error, high speed

Hydraulic system is equipped with water cooling system

High speed mandrel speed 2800rpm, inverter control, speed adjustable

Automatic loading, unloading Main Technical Data of Tube Spinning Machine

-

- Steel Tube (Cylinder) Necking-in & Closing Machine

Our steel tube (cylinder) necking-in & closing machine uses an automatic medium frequency heating method for hot spinning. It can be used for both necking in and closing steel tubes and cylinders. It can close flat ends, spherical ends and elliptical ends, with a freely adjusted necked in mouth diameter.

-

- Gas Spring Making Machine

We have complete machines for producing gas springs:

- Gas spring cylinder necking-in & grooving machine

- Gas spring seal press fitting machine

- Gas spring piston spin riveting machine

- Gas spring air filling machine

- Gas spring testing machine

- Gas spring marking machine

-

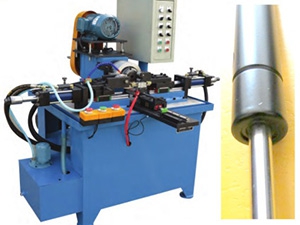

- Tube Cutting Machine

The tube cutting machine is a NC cut-to-length machine for straightening coil copper tubes and cutting it into the length required, automatically. It adopts special cutting technology, resulting in chipless cutting and small deformation of the cutting section.

-

- Copper Tube Flange Hole Punching Machine

This copper tube flange hole punching machine is specially designed for punching holes on copper pipes used in radiators for air conditioner.

Servo material feeding, hydraulic punching

NC control, convenient operation

-

- Tube End Forming Machine

The tube end forming machine is specially offered for tube end expanding, reducing, tapering, bellmouth forming, positioning ring forming, and so on. The pipe processed with our pipe end forming machine is generally used in the industry such as air condition, heater, and automobile. The tube end forming equipment can be designed with single station, three stations, four stations, five stations, and six stations.

-

- Extruded Fin Tube Machine

Tool holder and its body adopt the advanced dual-circular key structure to withstand torque and achieve accurate and reliable displacement.

Tool holder adopts split type design, making blade installation, debugging and cleaning operations easier.

-

- Oval Tube Finning Machine

The heat exchanging oval tube finning machines are widely used in air cooling systems of power station and chemical plant. The tubes use an oval tube as a carrier, which is different to other traditional cooler fin tubes.

-

- Copper Tube Rolling Machine

The copper tube rolling machine is configured according to the required diameter of finished product (copper tube). In general, our production line consists of melting furnace and caster, tube rolling mill, double-serial drawing machine (or triple-serial drawing machine), vertical type drawing machine, as well as auxiliary equipment, and so on.

-

- Large Diameter Culvert Tunnel Pipe Machine

Our large diameter culvert tunnel pipe machine is particularly developed for producing corrugated spiral steel pipes with large diameter. For high automation, the tunnel pipe machinery is equipped with PLC.

English

English Español

Español Русский

Русский Português

Português Français

Français العربية

العربية