- Home

- Products

- Transformer Making Machine

- CNC Coil Winder

CNC Coil Winder

Different coils require different CNC coil winding machines. Some of these coils include air-core coils, miniature toroidal coils, self-boarded bobbin free coils, speaker voice coils, wireless charging coils and transformer coils.

Multi-Axis Air Coil Winding Machine

We provide fully automatic 3-axis CNC machines for winding multi-layer air core coils. They can wind a maximum of 4 layers in round or rectangular bobbin free coils.

Main Features

- Machines of different capacities for different wire gauges: 0.2-1.0mm, 1.0-2.0mm, 2.0-4.0mm

- High precision ball screw and bearings with high precision and long life

- All three axes are controlled by servo motor, meaning low noise and stable operation.

- CNC control, simple operation, easy programming

- Optional wire stripping machine and tinning device

Photos

Technical Data

| Item | KXJ-013 | KXJ-033 | KXJ-033A |

| Suitable wire diameter | 0.2-1.0mm | 1.0-2.0mm | 2.0-4.0mm |

| Suitable air core coils | Single-layer | Multi-layer | |

| Stripping method | 3 diamond blades, centrifugal type | Servo stripper | |

| Max. guide head stroke | 90mm | 65mm | |

| Max. lead wire length | 30mm | ||

| Final lead wire position | Freely adjustable | ||

| Main spindle speed | 0-3000 rpm | 0-1500 rpm | |

| Max. production speed | 50 pcs/min | 30 pcs/min | |

| Air coil winding direction | Clockwise / anti-clockwise | ||

| X-axis setting range | 0.1º-359.9º | ||

| Y-axis setting range | ±0.1º - ±99C359º | ||

| Winding spindle stop precision | 0º | ||

| Winding set resolution ratio | 0.1º | ||

| Stripping motor | AC100W | AC 150W | |

| Tinning oven power | 400W | ||

CNC Wireless Charging Coil Winder

The CNC wireless charging coil winder is specially designed for automatically winding wireless charging coils. It is suitable for strand wires and silk-covered wires.

Main Features

- Hot air bonding

- Fully automatic 4-axis servo motor control

- The wire feeding device uses an SMC rodless cylinder and HIWIN linear guide

- Internationally known brand name PLC control system

- Full seal protection enclosure, clean and good safety

Photos

Main Technical Data

| Item | KXJ-064 |

| Number of spindles | 4 |

| Winding wire section range | 1-8mm2 |

| Suitable wireless charging coils | Both transmitting and receiving coils |

| Bonding method | Hot air blowing |

| Finishing lead position | Arbitrary |

| Flying spindle speed | 0-3000 rpm |

| Winding spindle speed | 0-3000rpm |

| Max. production speed | 2 pcs/min |

| Winding direction | Clockwise / anti-clockwise |

| X-axis setting range | 0 - ±999999C359º |

| Y-axis setting range | 0 - ±999999C359º |

| Winding spindle stop precision | 0º |

| Winding set resolution ratio | 0.1º |

| Beginning lead length | Min. 10mm, max. 30mm |

| Finishing lead length | Min. 10mm, max. 50mm |

CNC Speaker Coil Fly Winding Machine

The CNC speaker coil fly winding machine is a CNC machine used for winding self-supporting speaker voice coils using wires that have been coated in a thermo-plastic adhesive. The wire is heated by a hot air supply as it is wound onto the coil, and each turn is bound together using the adhesive. Finished coils are removed from the tool and automatically ejected from the machine onto a rotating unloading tool.

Main Features

- Fly winding design, multi-station winding & unloading

- Imported high precision ball screws & bearings, more accurate winding & guiding, longer life

- Two axis servo motor drive

- The CNC control system uses a microcontroller for simple operation and easy programming

- Low noise level

Photos

Technical Data

| Item | KXJ-082 |

| Number of spindles | 2 |

| Winding wire range | 0.02-0.1mm |

| Bonding method | Hot air |

| Max. stroke of guide head | 65mm |

| Lead position | Arbitrary |

| Spindle speed | 0-3000 rpm |

| Max. production speed | 5 pcs/min |

| Air coil winding direction | Clockwise / anti-clockwise |

| Y-axis setting range | 0 - ±999999C359º |

| Winding spindle stop precision | 0º |

| Winding set resolution ratio | 0.1º |

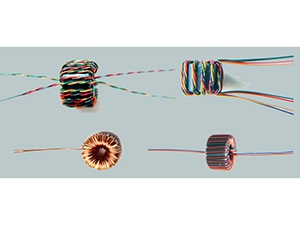

CNC Miniature Toroidal Coil Winder

Description

The CNC miniature toroidal coil winder is used to wind 4 twisted wires into super miniature toroidal cores. It is a fully automatic machine, with automatic core feeding, wire accumulation, twisting, winding and finished coil unloading. We also offer other miniature toroidal coil winders for different wire winding purposes.

Main Features

- Separate accumulating speed & length control

- Separate winding speed & turn control

- Optical fiber sensor plus dual digital displayer for turn controlling

- Variable winding pitch, programmable

- Servo motor drive, high precision, stable speed switching

- Fully automatic, continuous working, numerous machines with few operators

Technical Data

| Item | Data |

| Miniature core ID | 1.27~2mm |

| Miniature core OD | 2~4mm |

| Miniature core height | 0.65~3mm |

| Suitable wire diameter | 0.07 ~0.127mm |

| Winding method | 4 wires twisted |

| Winding turns | 9~16 |

| Continuous production delay time | Less than 2% |

| Winding speed | 4~6s per piece |

| pass percent | >99.5% |

| Machine dimension | About 850 x 550 x 1400mm |

| Machine weight | About 450kg |

English

English Español

Español Русский

Русский Português

Português Français

Français العربية

العربية